Wet Sump Lubrication System

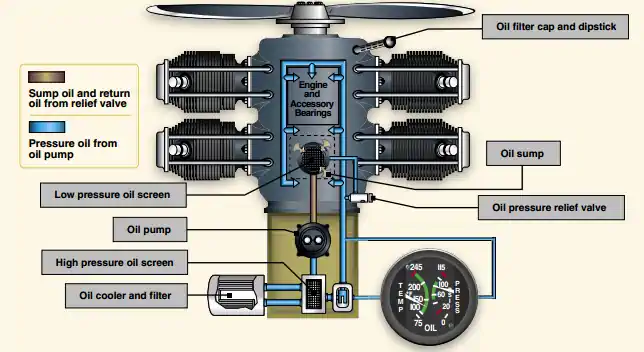

Wet sump lubrication system. After the oil passes through the engine it returns to the sump. Two Basic types of librication system used in an aircraft. After lubricating these parts the oil Bows back to the sump by gravity.

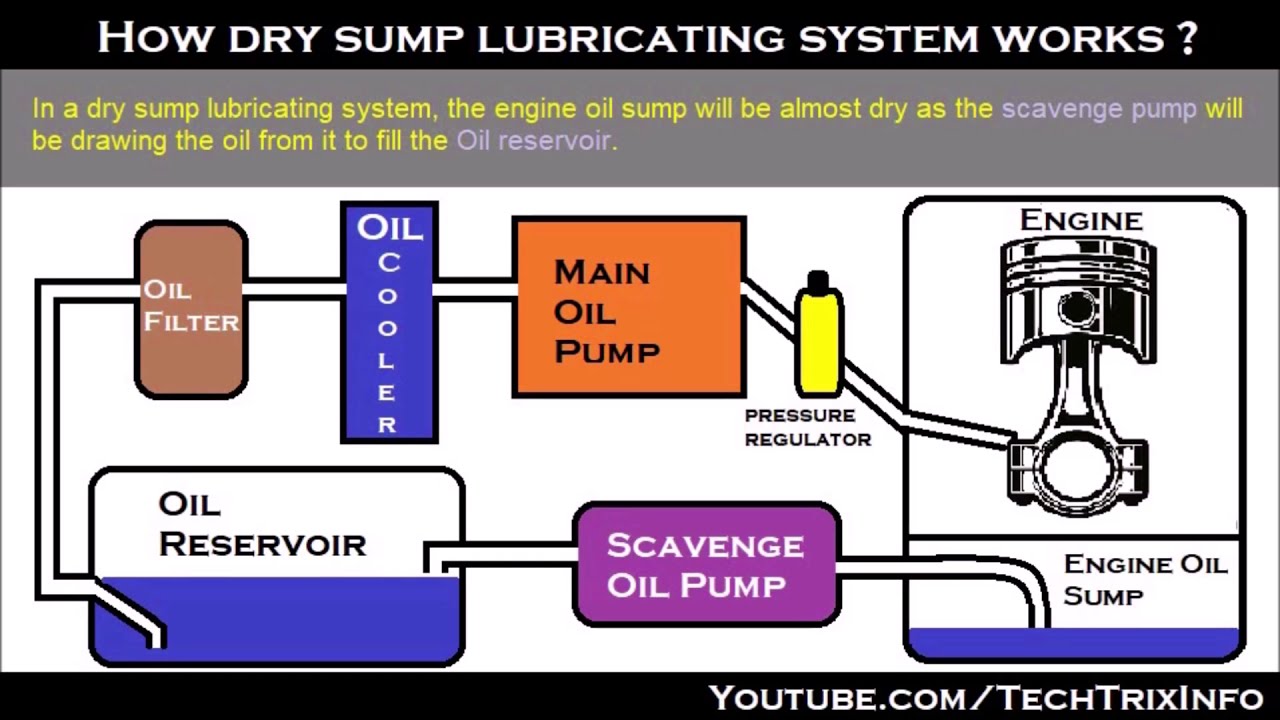

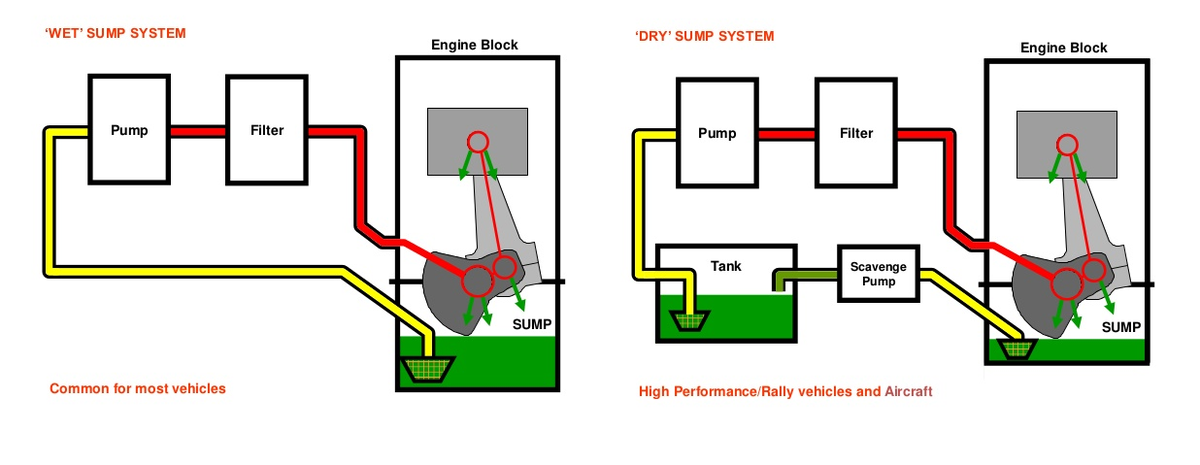

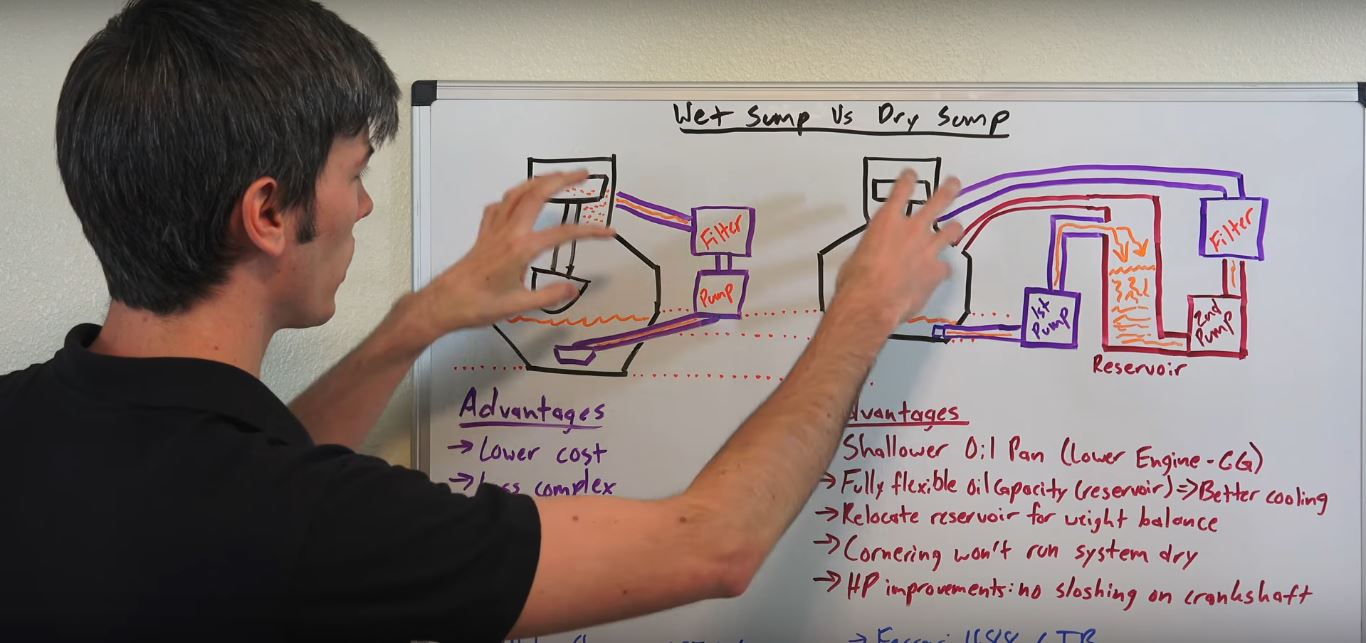

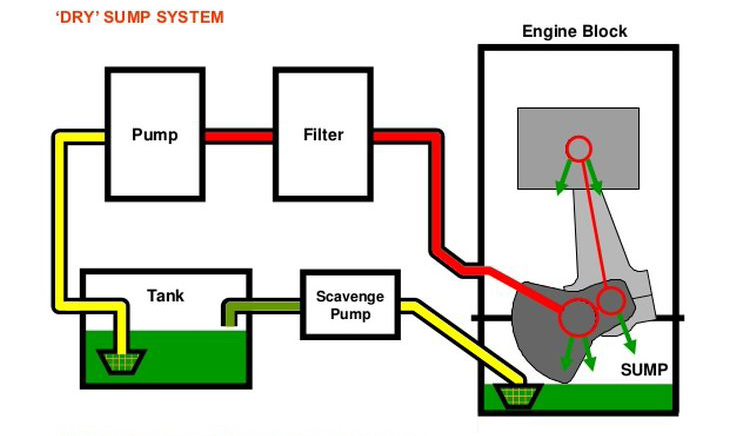

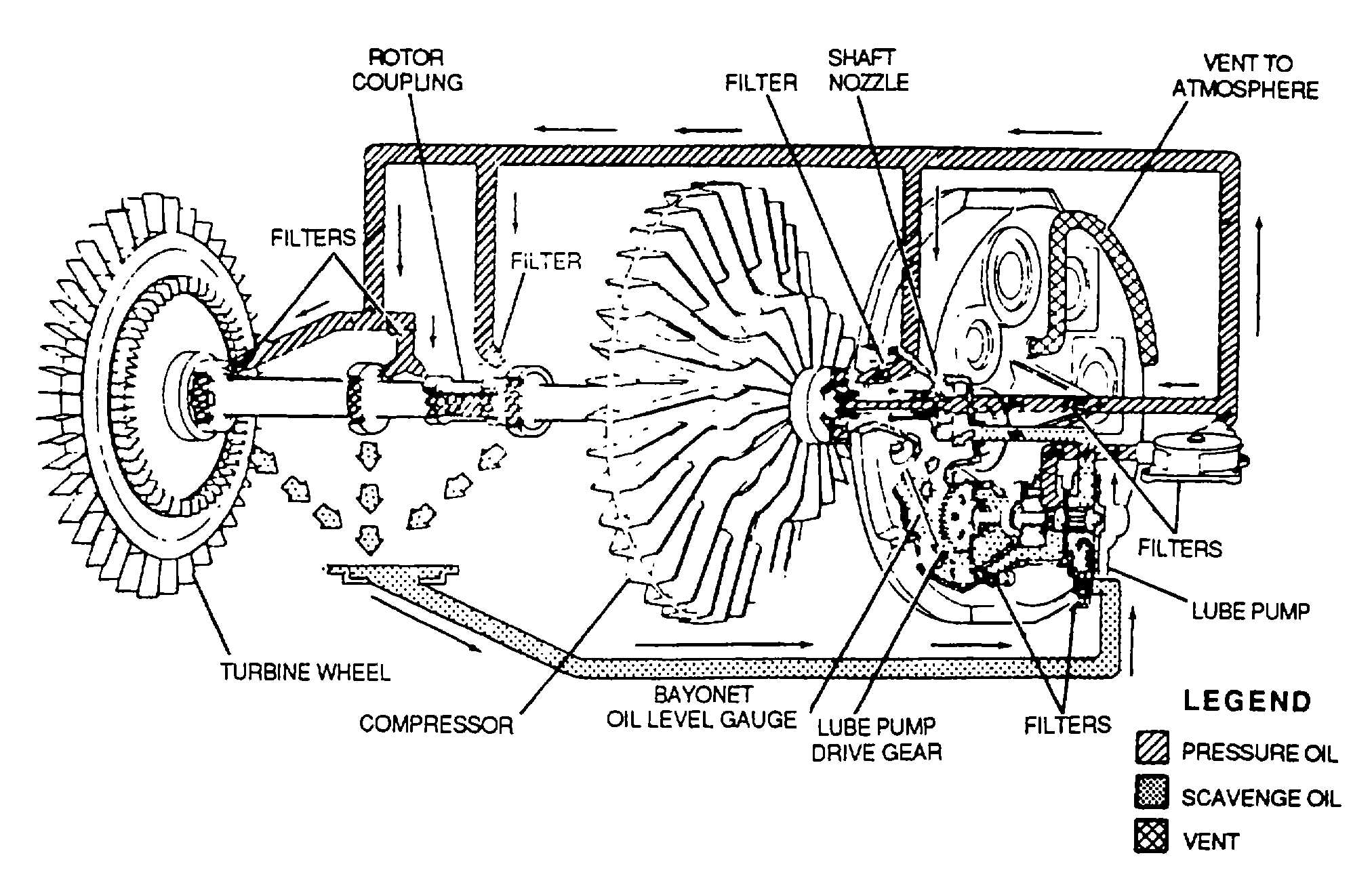

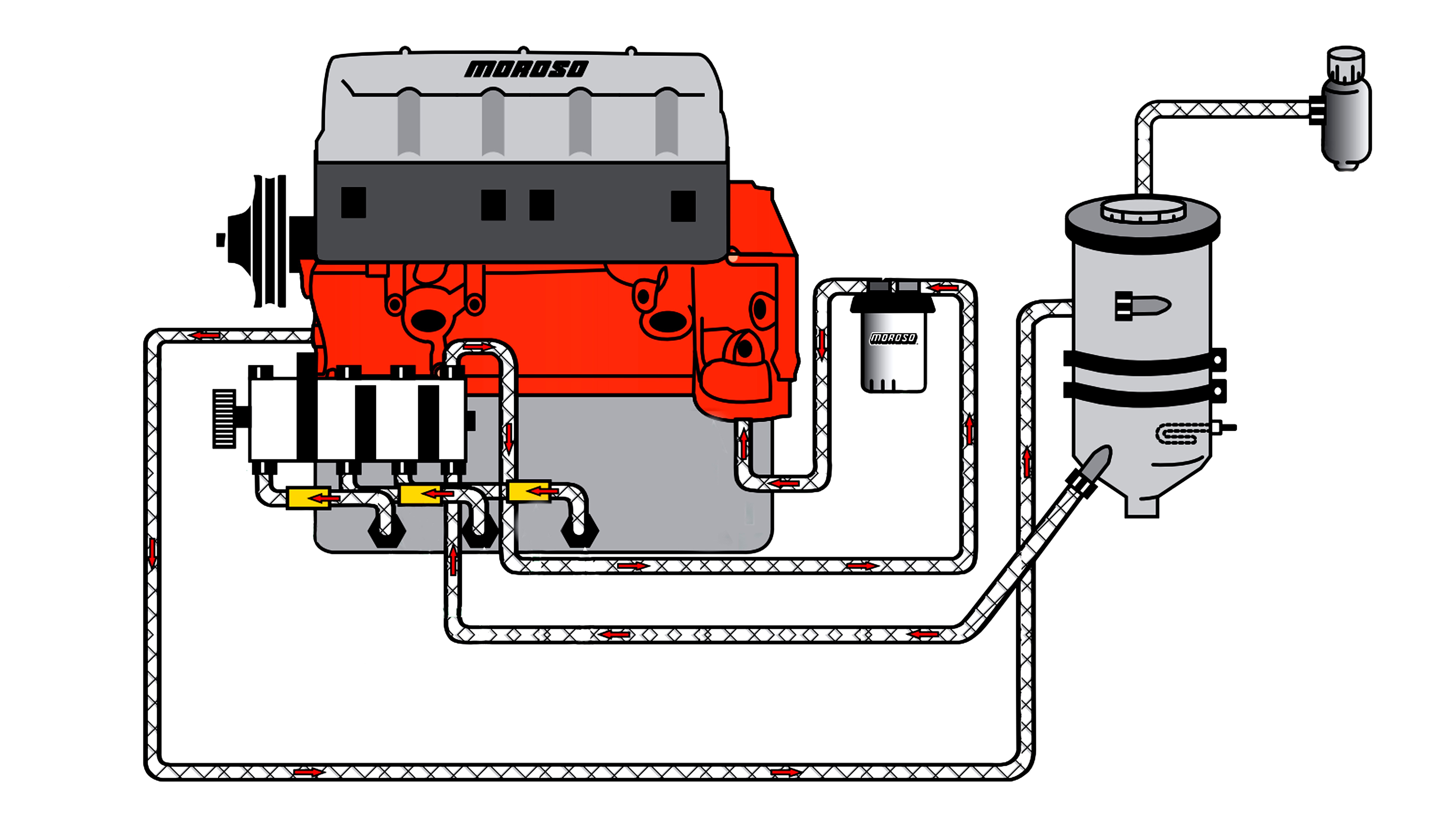

Within piston engines a wet sump is part of a lubrication system whereby the crankcase sump is used as an integral oil reservoir. A wet sump system is based off the original oiling system and can be enhanced with aftermarket parts. A dry sump system is meant for the top levels of racing where maximum power and control are necessary.

Three types of Piston Rings Compression Rings Oil Control Rings Oil Scraper Rings 431 434. Although a Wet Sump system is essentially the same system. Climbing-Oil Lubrication Gears rotating through a wet sump lift clinging oil into gear mesh zones.

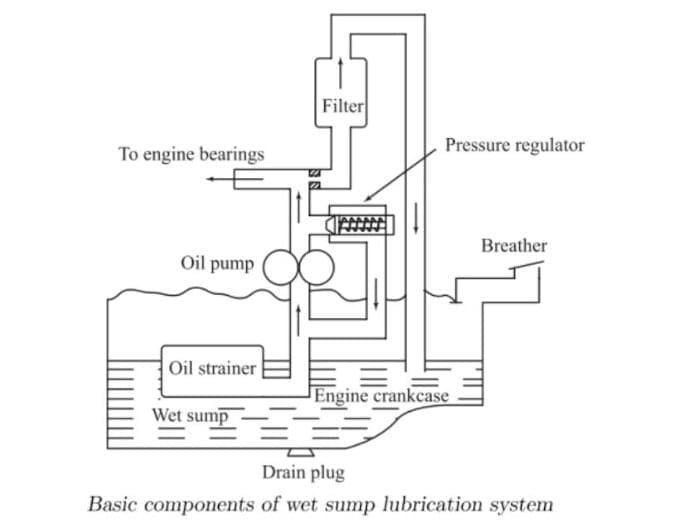

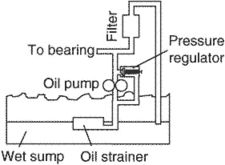

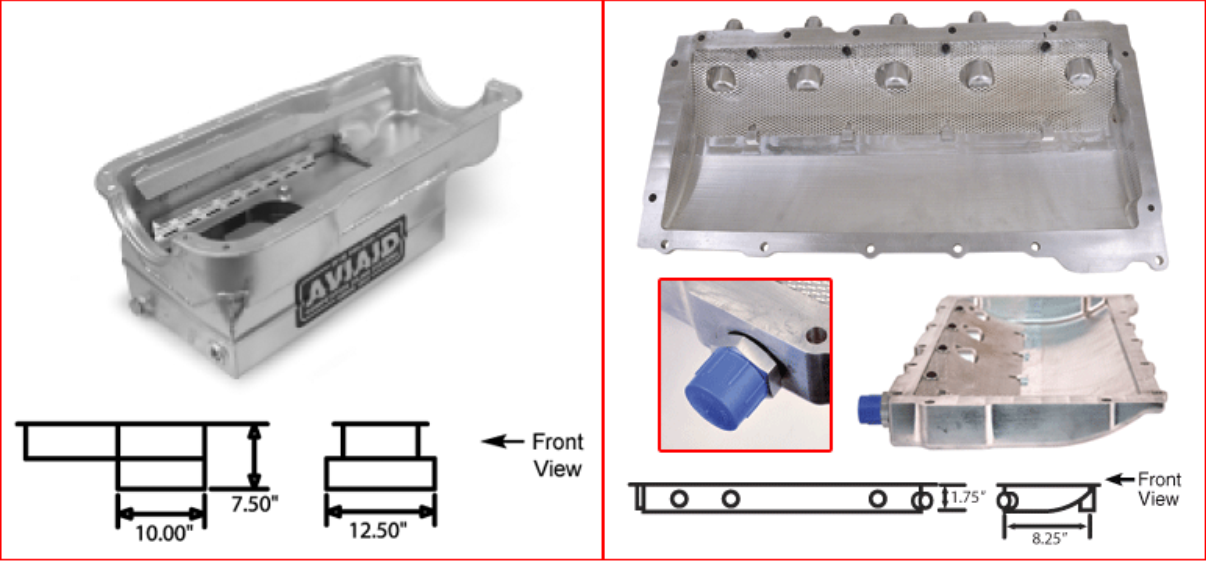

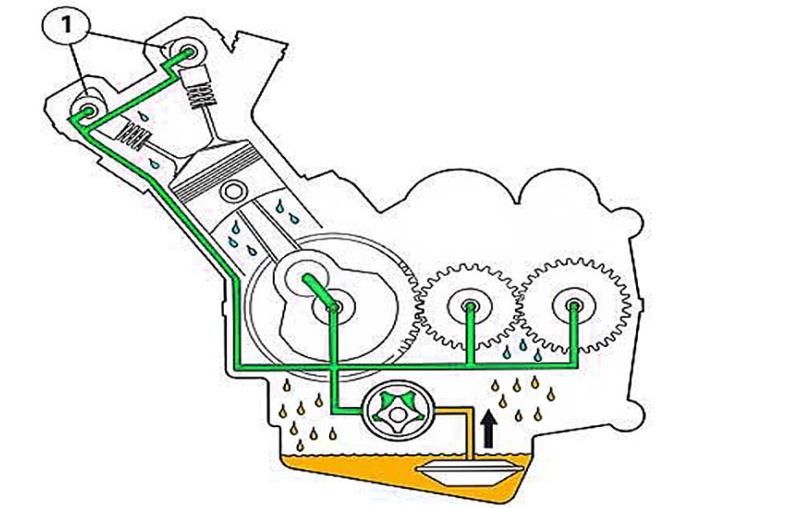

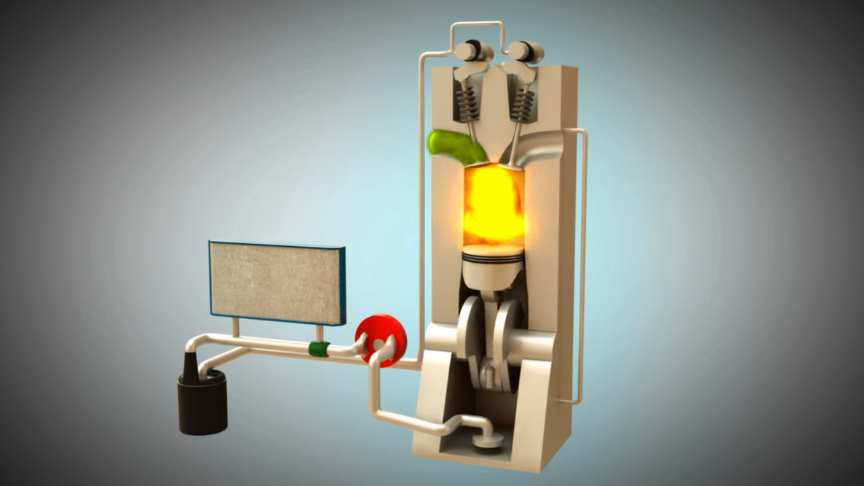

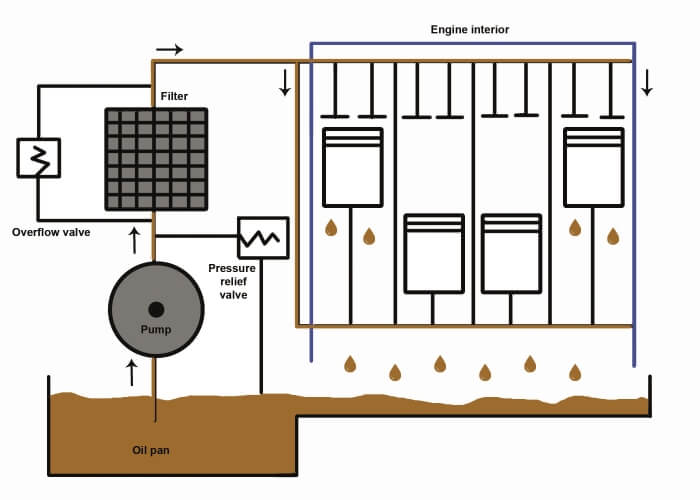

These wet sump systems are one of the simplest systems in every engine. Oil is carried in a sump which is an integral part of the engine Figure 2 The main component is the oil pump which draws oil from the sump and routes it to the engine. This scheme comprises of a big oil storage capability at the crank chamber foundation.

The oil pan serves as both the oil tank holding the supply of lubricating oil and the oil sump where oil eventually collects after making its way through the engine. This type of lubrication is often used in passenger cars. Wet sump systems maintain oil in reservoirs integral to the engine while dry sumps do not leaving the sump dry Wet-Sump.

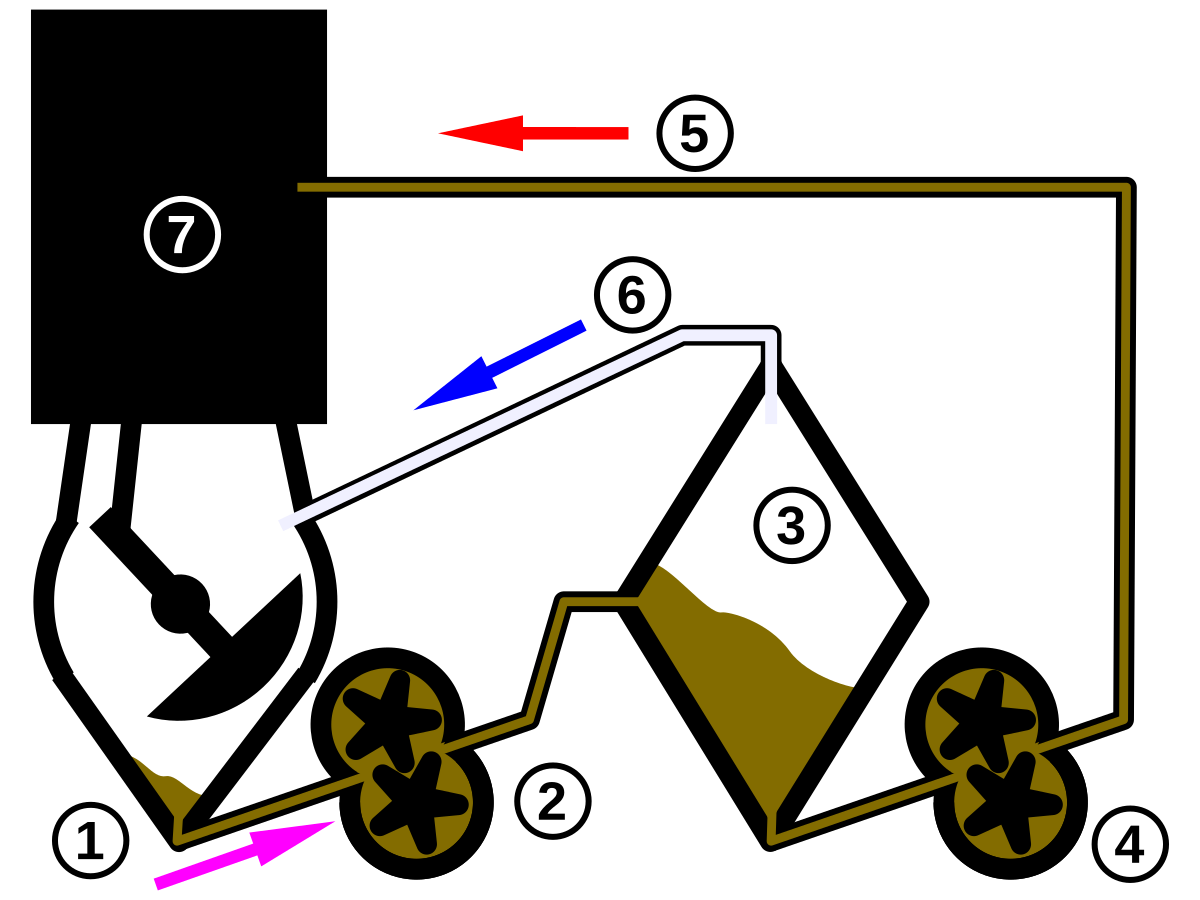

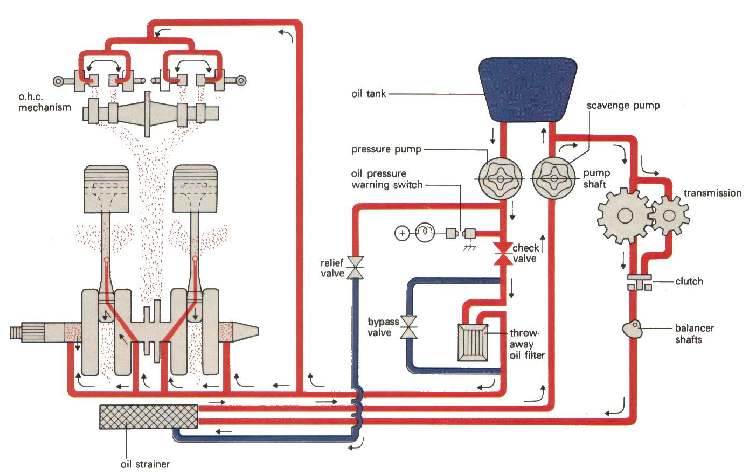

Piston engines are lubricated by oil which is pumped into various bearings and thereafter allowed to drain to the base of the engine under gravity. It is collected up by a pump and circulated through the engine lubricating system. Wet sump Dry sump 428 430.

Oil tanks are usually constructed of aluminum alloy and must withstand any vibration inertia and fluid loads expected in operation. Four Types of Piston Head Recessed Head Dome Head Truncated Cone Head Cupped Head 435 437.

After the oil passes through the engine it returns to the sump.

Components of a wet sump system are similar to a dry sump system except for the location of the oil supply. Oil tanks are generally associated with a dry sump lubrication system while a wet sump system uses the crankcase of the engine to store the oil. This animation explains the basic principle of wet sump lubrication. Three types of Piston Rings Compression Rings Oil Control Rings Oil Scraper Rings 431 434. Splash Lubrication Gear movement passing through an oil sump produces a splash or mist throughout the gearset to wet machine surfaces. In this system oil is transported to various engine parts with a sump strainer. TYPICAL WET SUMP SYSTEM In a typical Wet Sump system oil is stored in the bottom of the pan and distributed throughout the engine by an internally-mounted pump. After the oil passes through the engine it returns to the sump. Three Functions of a piston ring Prevent leakage of gas.

Two Basic types of librication system used in an aircraft. The use of a wet or dry sump oil system is usually based on the level of competition and a racers budget. This allows for lighter lubrication system and this system performs better in racetrack conditions. It is collected up by a pump and circulated through the engine lubricating system. Answer 1 of 4. Three Functions of a piston ring Prevent leakage of gas. What are the types of lubrication systems.

Post a Comment for "Wet Sump Lubrication System"